Explore new trends in Precision aluminum casting for aerospace applications

Wiki Article

Understanding the Value of Light Weight Aluminum Spreading in Modern Production Processes

Aluminum spreading has actually emerged as a necessary part in contemporary production. Its resilient and light-weight nature adds considerably to numerous industries, from automotive to electronics. On top of that, developments in casting strategies boost manufacturing efficiency and quality. As manufacturers look for innovative options, the duty of aluminum spreading in sustainability comes to be significantly important. This discussion will certainly discover the complex importance of light weight aluminum spreading and its effects for the future of manufacturing. What exists ahead in this evolving landscape?The Benefits of Light Weight Aluminum Casting in Production

Aluminum casting deals countless advantages that boost its allure in modern production processes. One major advantage is its light-weight nature, which brings about lowered power intake and boosted gas effectiveness in transportation applications. Additionally, light weight aluminum's exceptional rust resistance extends the life-span of actors products, making them more sturdy in different atmospheres. The material also facilitates intricate layouts and complicated geometries, allowing suppliers to develop parts that satisfy accurate specifications.Furthermore, light weight aluminum casting flaunts a reasonably low melting factor, which saves energy throughout the manufacturing process. This attribute additionally allows rapid cycle times, increasing total efficiency. Furthermore, the recyclability of aluminum adds to sustainability initiatives, as recycled light weight aluminum needs considerably much less energy to procedure compared to key aluminum. Collectively, these advantages placement aluminum casting as a necessary method in modern manufacturing, providing to the demands for effectiveness, performance, and ecological obligation.

Applications of Aluminum Spreading Throughout Industries

While different materials are utilized in manufacturing, aluminum casting has ended up being a pivotal approach across numerous markets due to its flexibility and functionality. This process is widely made use of in the vehicle market for generating light-weight engine blocks, transmission situations, and numerous elements that enhance fuel effectiveness. In the aerospace industry, aluminum casting is essential for developing intricate components that call for high strength-to-weight ratios, adding to boosted airplane performance.In addition, the electronic devices sector depends on aluminum castings for warm sinks and real estates, where thermal monitoring is vital for device durability. The building and construction sector also takes advantage of light weight aluminum casting in the kind of building elements and structural components that combine visual allure with longevity. Furthermore, the customer items sector utilizes light weight aluminum spreadings for kitchenware and showing off tools, leveraging the product's exceptional rust resistance and aesthetic coating. Generally, aluminum spreading offers as a foundation in modern production, supporting diverse applications throughout various areas.

The Function of Aluminum Spreading in Sustainability

Sustainability has come to be a focal factor in manufacturing practices, and light weight aluminum casting plays an important role in advertising ecologically pleasant options. The process of light weight aluminum casting is naturally sustainable due to the product's recyclability. Aluminum can be reused multiple times without shedding its buildings, greatly lowering energy intake and resources needs. This reusing process takes in just about 5% of the energy needed for main light weight aluminum manufacturing, causing a remarkable decrease in carbon emissions.Light weight aluminum casting promotes the production of lightweight parts, which contribute to power performance in various applications, particularly in the aerospace and auto sectors - Precision aluminum casting. Lighter cars take in much less gas, more minimizing environmental influence. Additionally, improvements in casting techniques are optimizing material use, lowering waste in making procedures. As sectors look for to straighten with sustainability objectives, light weight aluminum spreading becomes a viable solution, supporting a circular economy and fostering liable manufacturing techniques

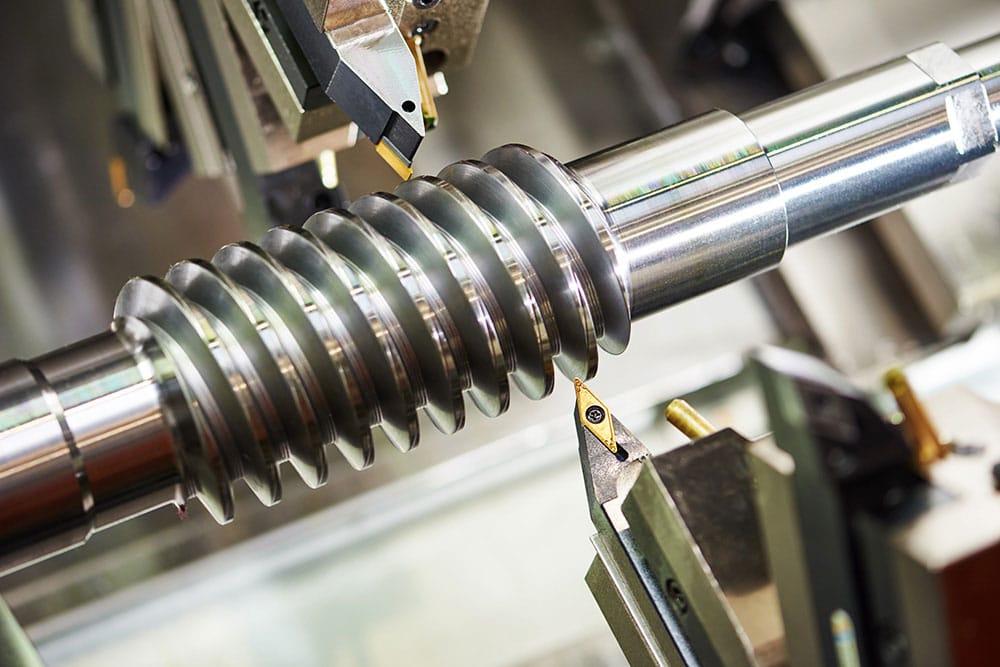

Technological Developments in Aluminum Casting Techniques

As industries develop, the adoption of innovative technologies in aluminum spreading strategies has actually transformed producing processes. The integration of computer-aided layout (CAD) and computer-aided production (CAMERA) systems improves precision and efficiency, enabling intricate geometries that were formerly challenging to produce. Advanced melting and spreading techniques, such as die casting and financial investment spreading, have improved the quality of light weight aluminum parts, reducing problems and reducing waste. The intro of automated systems and robotics in casting operations has structured process and increased performance. These innovations likewise enable real-time monitoring and information analytics, promoting better decision-making and quality control. Furthermore, the advancement of new alloys and warmth therapy processes has broadened the efficiency abilities of cast aluminum items. Jointly, these technical innovations not only enhance production effectiveness yet also contribute to the sustainability of aluminum casting in modern-day manufacturing.Future Patterns in Aluminum Spreading and Its Effect On Advancement

Arising trends in aluminum spreading are positioned to reshape the manufacturing landscape, driving development Click Here across different fields. One substantial pattern is the combination of sophisticated automation and robotics, which improves precision and efficiency in production procedures. Furthermore, the increase of additive manufacturing strategies is enabling a lot more complicated layouts, decreasing product waste and production time. As sustainability comes to be a top priority, the market's concentrate on reusing light weight aluminum and utilizing green methods is anticipated to grow, aligning with global ecological goals.Furthermore, the development of clever casting innovations, consisting of real-time monitoring and information analytics, is set to improve quality assurance and operational efficiency. These innovations will assist in the production of lighter, stronger, and a lot more long lasting aluminum components, accommodating markets such as auto and aerospace. Ultimately, these trends will certainly not just maximize manufacturing procedures but likewise inspire new applications of aluminum spreading, promoting a society of advancement and versatility out there.

Frequently Asked Inquiries

What Is the Background of Light Weight Aluminum Casting in Production?

Exactly How Does Aluminum Spreading Compare to Other Steels?

Aluminum casting offers advantages such as light-weight properties and rust resistance contrasted to other metals. Aluminum Foundry. It assists in complicated shapes and boosts energy effectiveness, making it a preferred choice in numerous production applications over much heavier alternatives like steel or ironWhat Are the Common Problems in Aluminum Spreading?

Usual issues in aluminum casting consist of porosity, contraction, misruns, and inclusions. These problems can arise from inappropriate pouring methods, inadequate mold layout, or polluted products, causing decreased architectural stability and performance of the end product.How Is the Quality of Aluminum Castings Tested?

The quality of light weight aluminum spreadings is examined through methods such as aesthetic assessments, dimensional dimensions, non-destructive testing strategies, and mechanical property evaluations, making certain that they meet specified criteria for performance and architectural honesty.

What Are the Security Actions in Aluminum Spreading Processes?

Precaution in light weight aluminum casting procedures consist of making use of individual safety equipment, correct ventilation systems, routine tools upkeep, training workers on dangers, and executing rigorous emergency procedures to decrease risks connected with heats and molten steel.The recyclability of light weight aluminum adds to sustainability efforts, as recycled aluminum calls for considerably less energy to process contrasted to main aluminum. While different my blog products are used you could check here in production, light weight aluminum spreading has ended up being a crucial approach across multiple industries due to its flexibility and functionality. Advanced melting and spreading methods, such as die casting and investment casting, have enhanced the high quality of aluminum parts, minimizing and lessening issues waste. Arising patterns in light weight aluminum spreading are positioned to improve the manufacturing landscape, driving advancement throughout different markets. Aluminum casting has actually advanced given that the late 19th century, originally establishing with the introduction of aluminum as a light-weight steel.

Report this wiki page